About technology

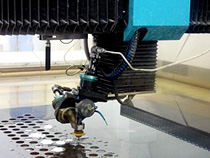

Our MACH 4 from FLOW enables 2D and also 3D cutting in unrivalled quality. Thanks to called cold cut, we transform/process essentially any kind of materials from fragile metals to very strong hardmetals.

The essence of dividing materials by Waterjet is abrading of divided material by press of Waterjet and added abraze. This process is almost the same as water erosion, but it is considerably accelerated and concentrated to the one place. The move of the cutting head and also trajectory of cutting is controlled by computer on the base in advance compiled/assembled program.

So it is possible to make also the most demanding shapes cut during the one operation. Another added value of this method is also the small material loss and high quality of cut.

Technical parameters

- Model

- MACH 4 from FLOW (2D and 3D cutting)

- Material

- maximum size 4000 x 2000 mm

- thickness to 150 mm (alternatively to 400 mm)

- any kind of materials from fragile metals to very strong hardmetals